SONORISE

Sonorise is a standing desk built for a corporate environment, to reduce the number of health problems associated with desk jobs. This desk functions as desktop organizer with minister riser, bluetooth speakers, subwoofer, desk drawer, and standing desk.

Project Brief

Our goal was to design a product family using a broad range of materials and forming methods.

This product family circulates around the function of desktop organization including a minister riser, bluetooth speakers, a subwoofer, and accommodations for office supplies storage.

Research Findings

Sitting time outside of work is negatively associated with the mental health of women.

3.5% of individuals between the ages of 20 and 59 meet physical activity guidelines of walking 30 minutes per day

As soon as you sit electrical activity in the leg muscles shuts off

Calorie-burning rate plunges to 1 per minute, a third of what it would have been if you would have been standing

Enzymes that help the breakdown of fat drop

AFTER 2 HOURS Good cholesterol drops 20%

AFTER 24 HOURS Insulin effect drop 24% and risk of diabetes rises

Standing for four hours a day can help you burn an extra 130 calories in a work day

By standing at a sit/stand desk for four hours a day, five days a week, and fifty weeks a year you could burn up to 32,500 calories which is equivalent to 11 marathons.

Standing desks increase muscle, mobility, & flexibility while decreasing body weight, blood sugar, and cholesterol.

User Archetype

Consumer Type: Early Adapter

Drive: Be healthy, stay healthy. Strives to be a role model to her children.

Philosophy: A happy workplace leads to a happy life. Goals are a stepping stone to success.

Frequented Brands: Whole Foods, Orange Theory, Lu Lu Lemon, Apple, Brookstone, etc.

Ideation Sketches

Refined Ideation

Material Selection

Brushed Aluminum

1/3 of the density of steel

High tensile strength

Superior malleability allows for easy extrusion

Corrosion resistance

Unlike most steel grades, aluminum does not become brittle at low temperatures. Instead, its strength increases

Clear Polycarbonate

Abrasion and chemical resistant Ease of fabrication and cleaning Improved weather-ability High impact resistanceHigh service temperature Excellent optical qualityHalf the weight of glass

Brushed Aluminum Edge Banding

Clean finishProtective to PCHigh impact resistanceCompliments pre-existing aluminum detailsModerately cost effective

Powder Coated Aluminum

Pleasing textureHigh impact resistanceLimitless variety of finishesComparably lightweight

Bovine Leather

Allows for traction Conveys qualityAges wellOrganic contrast within an industrial productElastic durability

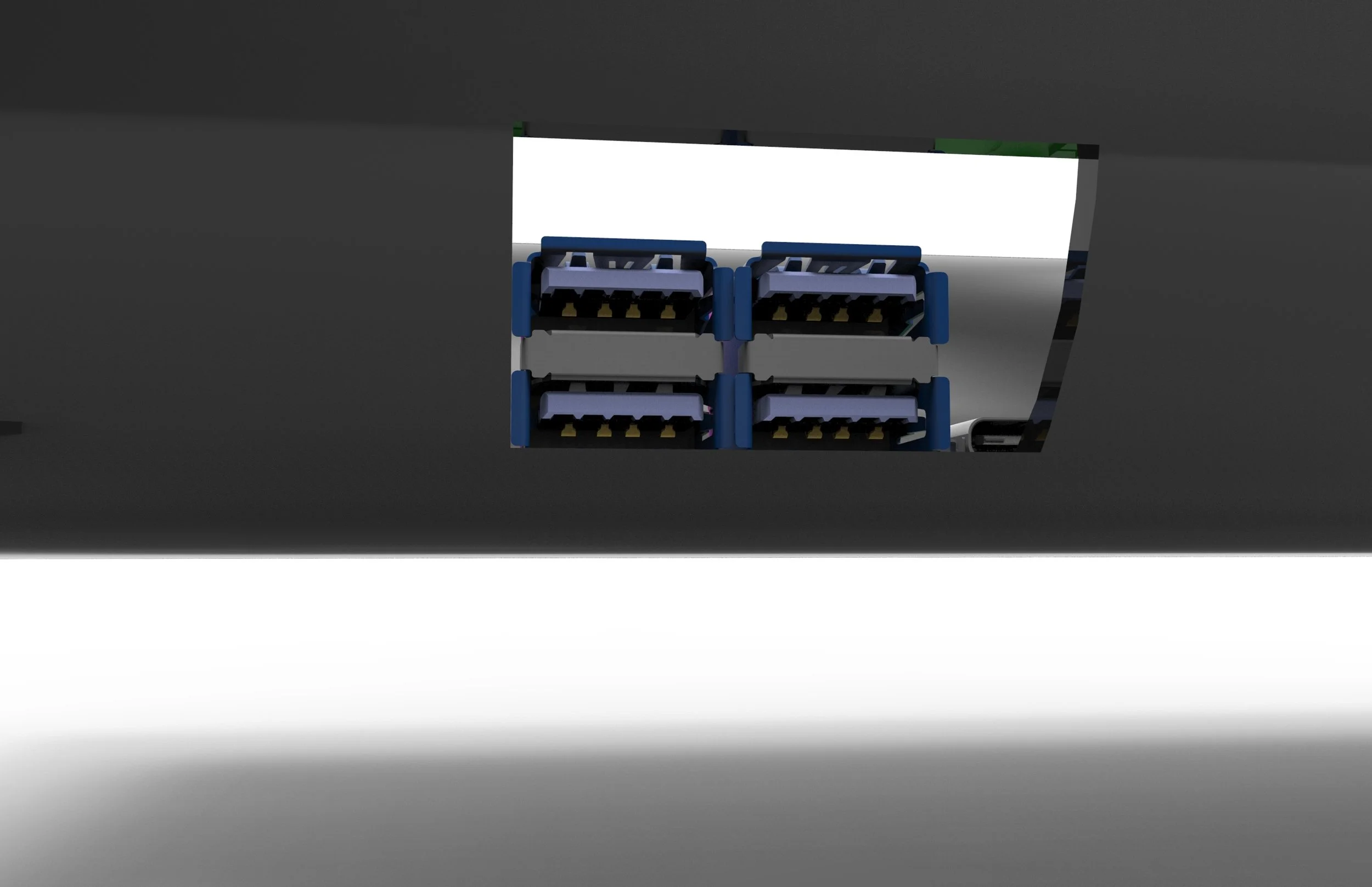

Gopher Speakers

The front speaker cover will be constructed out of pre-perforated aluminum that will be extruded and press broken to give optimal sound impedance for a reasonable manufacturing cost.The main speaker body will be cold extruded out of aluminum and the holes will be punched out from the body in a secondary procedure.The top and bottom of the assembly function as extrusion caps that would be die casted to make sure that they are the exact dimensions to hide the seams while keeping the smooth finish. The caps will pressure fit, compromising a small annular rib in the process.

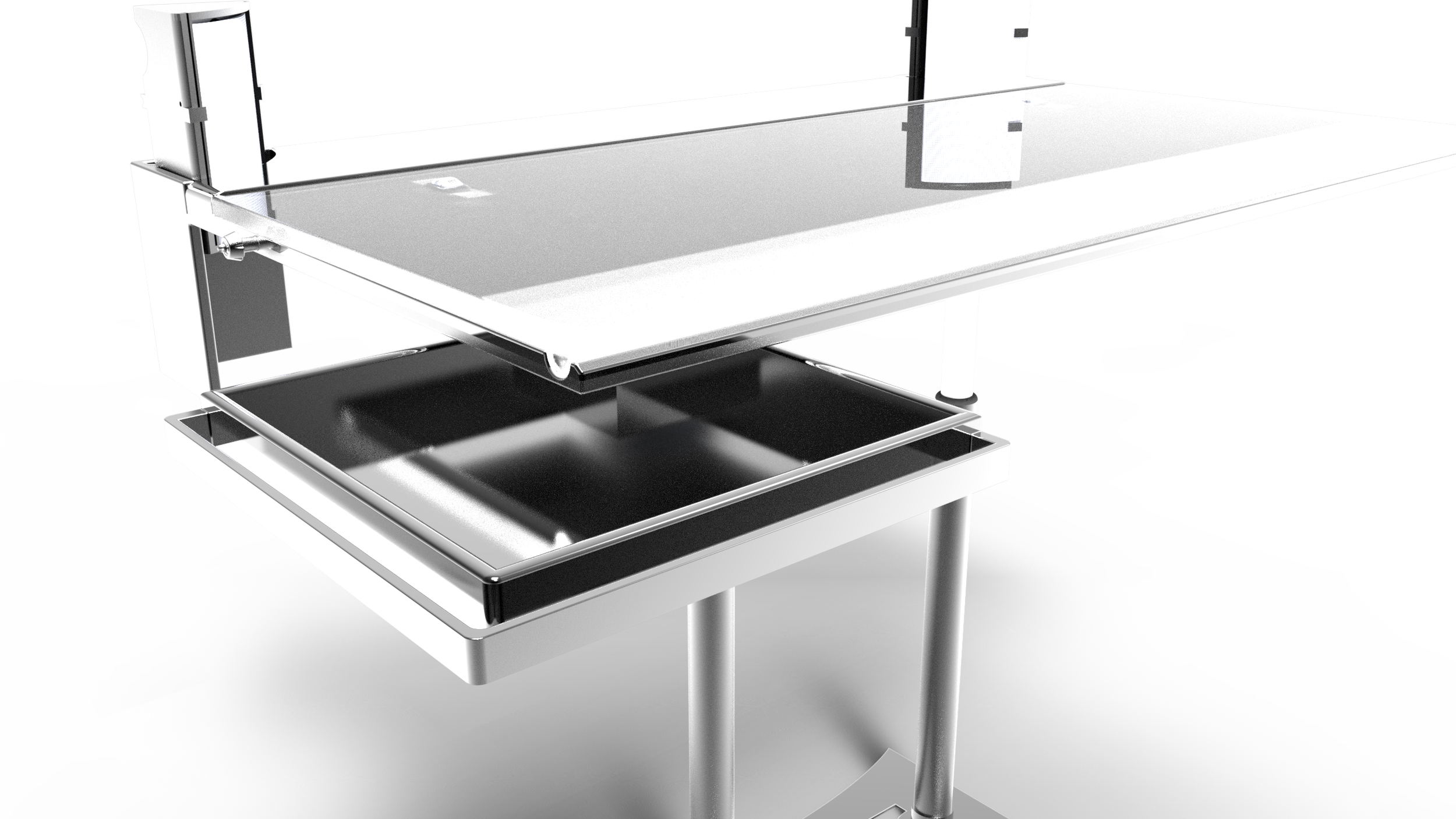

Desktop

The Polycarbonate top can be extruded into the rectangular piece that will be used for sketching at different angles.The base will be made out of brushed aluminum that is Hydroformed into the complex shape we need for the cavity and Gopher Speaker holders.The piece will then be stamped with rivnuts installed to fasten to the rest of the table components.

Gas Lifts

The external and internal shafts will be extruded out of aluminum and closed with the plastic caps used to keep it pressurized.The internal components of the lifts will be investment casted to keep the parts precise enough to hold pressure while also eliminating secondary machining the parts will need.

Corner Drawer

The corner drawer sits on a rail that connects from the bottom face of the desk to the bottom of the drawer by means of bolts with accompanying nuts, while the drawer simply rests on the rail system.The drawer would be constructed by means of MIM due to its lack of undercuts, while the rail is an extrusion placed through the press brake. Secondary procedures are required to drill necessary holes and insert threading.